x

I

n

k

a

r

p

Flex-Mount

Flex-Mount Integration

Distributor & Service Provider In India

Inkarp Instruments, a trusted Nanosurf partner, presents the Flex-Mount Integration in India, enhancing atomic force microscopy (AFM) capabilities.

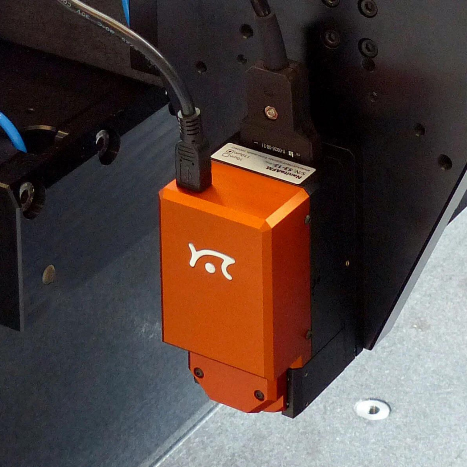

The essential AFM for custom integration

Flex-Mount is a unique AFM that can be configured to acquire high-resolution information on large, non-planar and demanding samples. The Flex-Mount solution combines the superior resolution and performance of the Nanosurf FlexAFM scan head with the integrability of the Nanosurf NaniteAFM. The result is an AFM that can easily be attached to one of Nanosurf’s large, custom-built motorized translation stages and is thus able to characterize the surface of samples with weights and dimensions virtually no other AFM system can handle.

- Proven performance and reliability

- Automated measurements for additional ease of use

- Customizable stages to handle large samples of any shape and size

| Flex-Mount scan head features | |

|---|---|

| General design | Mountable scan head with tip scanner; Flexure-based electro-magnetically actuated XY-scanner with superb linearity; Piezo-based Z-actuator; Optical Z-position sensor; Closed loop Z-control |

| Laser / detector | High-speed, low-noise 4-quadrant photodiode detector; near-infrared SLD; laser on/off through software and scan head tilting; optical filters for use with optical microscope phase contrast and fluorescence |

| Approach | 50 mm z-stage with step-by-step approach; software-driven motorized coarse movement and automated final approach |

| Cantilever holder | Automatic self-alignment for cantilevers with alignment grooves. Manual laser adjustment possible for special cantilevers. |

| Sample observation | Top and side view in air and liquid; White LEDs (brightness 0–100%); Axial illumination for top view |

| Operating modes | Static Force, Lateral Force, Dynamic Force, Phase Contrast, MFM, EFM, KPFM, Piezo Force, Force Modulation, Scanning Thermal, Spreading Resistance, Multiple Spectroscopy modes, Lithography and Manipulation modes. Some modes may require additional hardware and/or activating of the respective C3000 controller options. |

| Security out option (for stage controllers) | Security mechanism to prevent severe scan head crash and to protect the sample. Includes table-top operating unit with emergency kill switch and manual security override for 3rd party stage control units by LSTEP or SmarAct. |

| Flex-Mount scan head specifications | |

|---|---|

| Sample size | Stage-dependent |

| Motorized approach range (at tip position; standard Z-stage) | 50 mm |

| Max. scan range (XY) | 100 µm (1) |

| Max. height range (Z) | 10 µm (2) |

| XY-linearity mean error | < 0.1% |

| XY-flatness at maximum scan range | typ. 5 nm |

| Detector bandwidth | DC - 4 MHz |

| Detector noise level (RMS) | typ. 60 pm / max. 100 pm (3, 4) |

| Z-sensor noise level (RMS) | typ. 180 pm / max. 200 pm (3) |

| Z-measurement noise level (RMS, static mode in air) | typ. 100 pm / max. 200 pm |

| Z-measurement noise level (RMS, dynamic mode in air) | typ. 35 pm / max. 50 pm |

| Scan head dimensions incl. Z-stage | 181 mm x 130 mm x 171 mm |

| Scan head weight | 1.25 kg |

| (1) Manufacturing tolerances ± 5% (2) Manufacturing tolerances ± 10% (3) Measured at 2 kHz (4) Measured with XYContr cantilever |

|

| C3000i controller — Core hardware specifications | |

|---|---|

| X/Y/Z-axis scan and position controller | 3× 24-bit DAC (200 kHz) |

| X/Y/Z-axis position measurement | 1× 24-bit ADC (200 kHz) |

| Excitation & modulation outputs | 2× 16-bit DAC (20 MHz) |

| Analog signal input bandwidth | 0–5 MHz |

| Main input signal capturing | 2× 16-bit ADC (20 MHz) 2× 24-bit ADC (200 kHz) |

| Additional user signal outputs | 1× 24-bit ADC (200 kHz) |

| Digital synchronization | Sync Out 1/2: digital outputs, signal range 0/5V TTL pulses |

| FPGA module and embedded processor | ALTERA FPGA, 32-bit NIOS-CPU, 80 MHz, 256 MB RAM, multitasking OS |

| Communication | USB 2.0 Hi-Speed to PC and scan head interface |

| System clock | Internal quartz (10 MHz) or external clock |

| Power | 90–240 V AC, 70 W, 50/60Hz |

| Cantilever specifications and requirements | |

|---|---|

| Width | min. 20 μm |

| Length | min. 40 μm |

| Reflective coating | Reflective coating recommended |

| Liquid measurements | Yes, with gold coating |

| Alignment grooves | Required by default Special cantilever holders without alignment grooves are available |

| Resonance frequency dynamic mode Easyscan 2 Controller | 15 kHz to 350 kHz |

| Resonance frequency dynamic mode C3000 Controller | < 4 MHz |

| Cantilever shape | Single rectangular cantilevers and multilever cantilevers (depending on scan head version and cantilever holder) |

| Chip thickness | 300 μm, 500 μm or 600 μm depending on cantilever holder |