HETTCUBE 400 | 400 R

HETTCUBE 400 | 400 R Incubators

Distributor & Service Provider In India

Inkarp Instruments, a leading Hettich partner, offers the HETTCUBE 400 and 400 R Incubators in India, delivering precise temperature control, advanced humidity management, and optimal atmospheric conditions for demanding microbiological, cell culture, and industrial applications. These large-capacity incubators feature intuitive touchscreen interfaces, alarm systems, and optional refrigeration (400 R) for versatile and reliable operation. With advanced features like temperature mapping, calibration, and validation, the HETTCUBE 400 series ensures compliance with strict regulatory requirements. Inkarp Instruments provides expert distribution, installation, training, and comprehensive after-sales support, empowering Indian laboratories and industries to achieve accurate and reproducible results.

EFFICIENT USE OF VALUABLE SPACE

With its volume and wide range of accessories the HettCube 400 incubator is well suited for all pharmaceutical, research and industrial applications.

This unit is also available with refrigeration and a temperature range from 0 °C to +65 °C (HettCube 400 R).

Facts & Numbers

INTERNAL VOLUME:

310 l

VALIDATED USABLE SPACE:

199 l

NUMBER OF PROVIDED TRAYS:

3 (2 Standard + 1 HTS)

ENERGY CONSUMPTION:

0.046 kWh/h

DIMENSIONS (W x D x H):

710 x 825 x 1,425 mm

CLINICAL MICROBIOLOGY, CLINICAL MONITORING

Clinical specimen taken from patients or obtained in the course of hygienic monitoring of hospitals are incubated to identify bacteria, fungi, and yeast.

INDUSTRY AND RESEARCH

In many fields microbiological examination is required. Food has to be monitored as well as drinking water or water from waterbodies. Cosmetic products have to be monitored, too. In research labs bacteria are grown for genetic tests or tests in molecular biology.

FACILITIES

- Microbiological labs

- Hospital labs

- Pharmaceutical labs

- Food analyzing labs

- Scientific labs in universities

- Cosmetic industry

- Food and beverage

- Agricultural industry

- Life Science

ACCESSORIES

WE HAVE THE RIGHT ACCESSORIES FOR YOU!

Get in contact with us, we are happy to assist you in choosing the right rotor and the accessories.

PARAMETERS FOR CONTINUOUS COOLING OPERATION

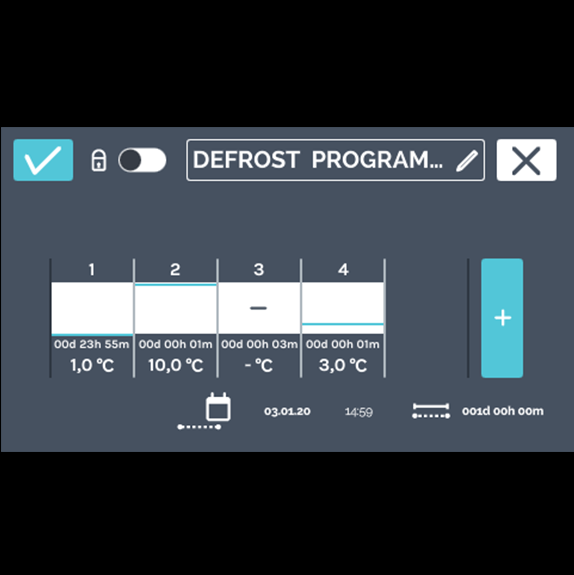

Hettich offers an alternative operating mode in its cooled incubators for special applications where low temperatures below 15°C are required over long periods. This ensures high temperature homogeneity and temperature stability. At the same time, the unit's compressor is better protected, which contributes to a longer service life of the unit and a reduction in energy consumption. Temperatures between +1°C and +5°C usually lead to icing of the cooling unit during continuous operation. If the cooling unit is briefly warmed up once a day, ice formation is reliably prevented. For this purpose, a DeFrost program can easily be created by the user with the help of the touch screen.

Example:

- Unit cools down to the individual temperature of the customer: in this example first segment to +1°C

- The cooling unit is briefly heated up: in this example second segment to +10°C for the duration of 1 minute

- The device remains in stand-by mode: in this example third segment for 3 minutes

- The unit cools down to an intermediate temperature, this must be 2°C above the set temperature: in this example fourth segment 3°C for Duration of 1 minute