Flow Cell

Flow Cell VCX 1500

Distributor & Service Provider In India

Inkarp Instruments, a trusted Sonics partner, presents the Flow Cell for VCX 1500 in India, a specially designed reactor for continuous-flow ultrasonic processing.

The flow cell enables continuous processing of 5L or more. The throughput rate depends on many variables including viscosity and desired degree of processing. The flow cell is recommended for the treatment of low viscosity samples which do not require extended exposure to ultrasonics. For optimum performance, when working on a flow through basis, pre-mixing the sample with a mechanical stirrer is recommended. Multiple units can be used in series to reduce processing time and/or maintain higher flow rates.

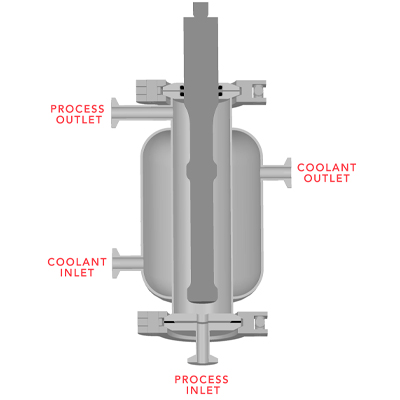

The process fluid is pumped into the flow cell through the inlet at the bottom. As the sample passes through the cavitation field at the tip of the flow cell probe, it is processed. The processed liquid exits the unit through an outlet port. The degree of processing can be controlled by adjusting the intensity of sonication as well as flow rate.

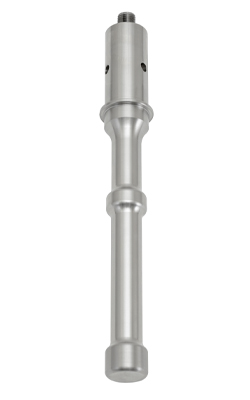

The 1" (25mm) high efficiency probe is included with the flow cell. All process connections are sanitary and the unit is easily disassembled for cleaning. All wetted parts are autoclavable. The flow cell is water jacketed to assist in cooling the sample fluid during processing. The chiller PART NO. 830-00906 is recommended for use when cooling the water jacket on the flow cell.

Use of the sound enclosure (part no. 830-00474) is always advised.

Part No.

VCX 1500HV

CROSS SECTION OF FLOW CELL

FLOW CELL ASSEMBLY

Part No.

630-0549

REPLACEMENT PROBE

Part No.

630-0625

Flow Cell Specifications

Material

316 stainless steel

Height

17" (432mm)

Width

16" (406mm)

Weight

12 lbs. (5.5 kg)

Operating pressure

Up to 100 psi

Internal volume w/probe

400mL

Product/Coolant Connectors

1/2" (13 mm) sanitary fittings