x

I

n

k

a

r

p

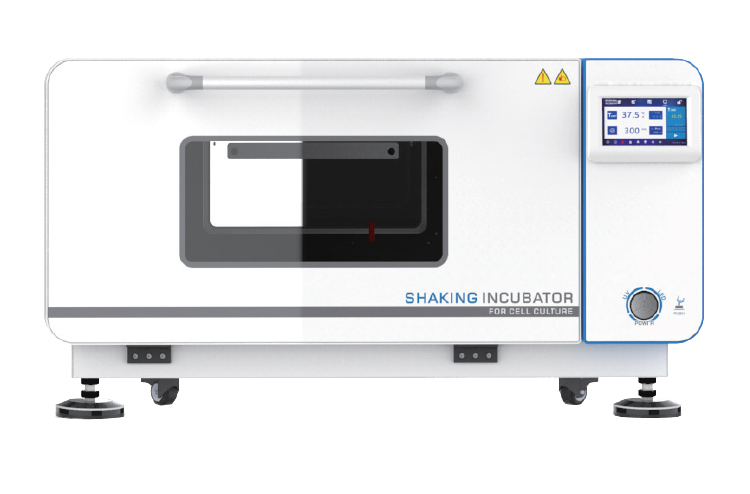

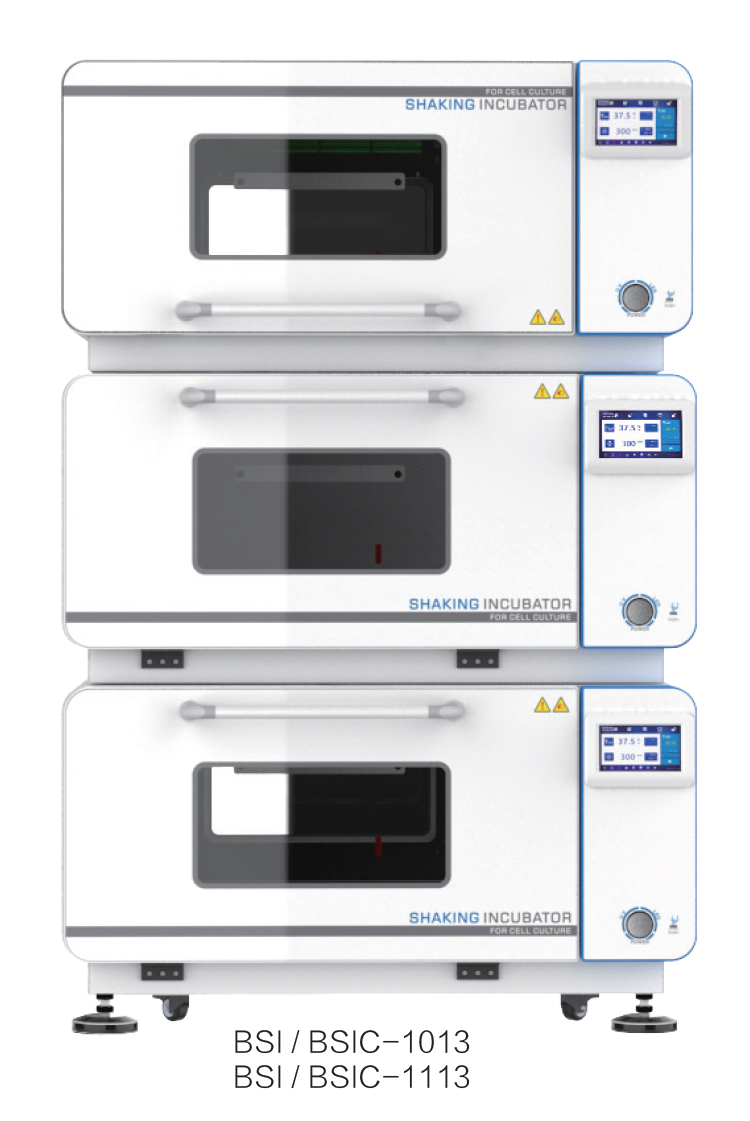

Stackable CO2 Incubated & Refrigerated Shaker

Stackable CO2 Incubated & Refrigerated Shaker

Distributor & Service Provider In India (BSIC-101, BSIC-102, BSIC-103, BSIC-111, BSIC-112, BSIC-113)

StackableCO2 Incubated and Refrigerated Shaker(Cooling+humidity control+CO2 control)

Application

It is widely applied in cell culture, fermentation, hybridization, biochemistry and cell tissue study in which temperature and shaking frequency requirements must be met. Moreover, static and dynamic culture of microbial cell and varieties of bacteria can be performed in the incubator.

Humanized design

- Delicate design incorporating the incubator and shaker in a stacking manner, featuring less space and higher utilization.

- Extraordinary fluorine-free design providing noise-free operation.

- Large color touch screen providing display of temperature, speed and working time in a continuous, accurate and real-time manner.

- Large observation window, SS304 working chamber, high quality aluminium-made shaking platform covered with anti-bacteria coating, easy to clean.

- Top and bottom-openingdoor, withdrawable shaking platform facilitating operation.

Quality assurance

- Timing configuration permitting temperature and shaking frequency control with microcomputer; internal power-off protection function allowing automatic re-startup after power restoration

- The key components such as compressor and circulating fan are the maintenance-free products of premium brands.

Continuous operation guarantee

- Low-heat-rejection brushless DC motor, featuring high start torque, wide range of speed regulation and free of maintenance, as well as continuous operation for a long period

Environmental temperature monitoring system

- An Independent environmental temperature detector able to automatically vary the shaking incubator heating system in response to variation of the environmental temperature in the labto prevent temperature overlimit in the incubator

Triple eccentric shaft balance drive

- Triple eccentric shaft balance drive process able to ensure that the sample on the shaking pallet is subject to shaking at the same speed. The load-bearing structure design providing excellent durabilityensure that the shaker can operate well at full rate and high speed.

Sterilization system (CO2 shaking incubator)

90℃ high temperature moist heat sterilization system

- Entire high-temp. moist heat sterilization inside the chamber (incl. temperature sensor, CO2 concentration sensor, fan, partition and stand), thoroughly eliminating the microbial contamination made by varieties of microorganism during cell culture, such as bacteria, mold, mycoplasma, etc., and consequently allowing users to work in a safe experimental environment.

- Simple operation: press on the (sterilization start) button in the control panel to allow the sterilization system to conduct thorough sterilization on all components in the incubator (including temperature sensor, carbon dioxide concentration sensor, fan, partition and bracket).

Carbon dioxide monitoring and control system (CO2 shaking incubator)

- Utilize the foreign infrared sensor able to accurately monitor CO2 gas at fast speed with freedom from impact of external temperature and humidity change. Uniform distribution of CO2 concentration can be steadily maintained despite frequent opening/closing the door by more than one operator. What user is expected to do is to put in place CO2 gas supply.

- The CO2 gas inlet is equipped with an adequate microbial filter able to filter off particles with grain size of ≥0.3μm, as high as 99.99%,so that bacteria, micronic dust particle and microbial contamination source in CO2 gas can be effectively eliminated.

Temperature and humidity control system (for CO2 shaking incubator)

- Use of temperature and humidity sensor operating at high temperature to ensure adequate temperature and humidity control in the incubator. Meanwhile, test temperature and humidity can be restored in a short time when user takes the sample out of the incubator or put it inside the incubator.

Door temperature heating and monitoring system (CO2 shaking incubator)

- The outer door and observation window can be heated. The door temperature varies in response to the incubator temperature and is slightly higher than the incubator temperature, thus preventing condensate formation on the door, facilitating access to viewing the entire test process and eliminating potential microbial contamination arising from condensate.

Functions expansion (optional)

- Illumination control. (To simulate natural growth environment)

- Humidity monitoring and control.

Safety function

- Door switchable to provide auto stopheating and shakeronce the door is openning, gentle air flowto eliminate temperature overlimit.

- Unique speed control circuit able to ensure steady shaker start, and prevent instrument damage by overspills.

- Independent temperature limit alarm system able to automatically stop heating once temperature limit is exceeded, thus ensuring operation at safety.

- The circulating fan can automatically operate at different speed, thus preventing sample evaporation arising from overspeed of the circulating fan.

- Standard USB data transfer port (U disk) or optional RS-485 port (either-or). Monitor temperature, speed, time and alarm via computer being connected. An embedded printer may be considered (optional)

Hierarchical authority management (optional)

- There are multiple accounts that can be assigned. Whenever necessary, the right to operate the equipment controller is separately assigned to administrator, operator and visitor

| Model | BSIC - 101 BSIC -111 |

BSIC - 102 BSIC -112 |

BSIC - 103 BSIC -113 |

|---|---|---|---|

| Display | 7 inch touch screen | ||

| Temperature Range | 4~65℃ | ||

| Uniformity | ±0.4(test point at 37℃ , Ambient at 25℃) | ||

| Temperature Resolution | 0.1℃ | ||

| Type of movement | orbital | ||

| Orbital diameter | 26mm | ||

| Speed range | 40~300rpm | ||

| Time setting range | 0~5999min | ||

| Operating mode | timer and continuous operation | ||

| Size of platform | Model 101:500×460mm; Model 111:760×460mm | ||

| Permissible shaking weight | Model 101:10Kg; Model 111:15KG | ||

| Dimensions (W x H x D) | 1000×670×920 1200×670×920 |

1000×1270×920 1200×1270×920 |

1000×1870×920 1200×1870×920 |

| heating method | Six-sided heating | ||

| CO2 control range | 0 ~ 20% | ||

| CO2 restore time | (Door open 30s, recovery to 5%)≤3min | ||

| CO2 control accuracy | ±0.1% | ||

| CO2 stability | ±0.1% (at 5% CO2) | ||

| CO2 sensor | IR sensor | ||

| Humidity control Range | 50%~95%RH | ||

| Humidity control accuracy | 85%~95% (at 37℃ ) | ||

| Humidity deviation | ±3% | ||

| Sterilization | UV sterilization+90℃ moist heat sterilization | ||

| Power | 1200W 1400W |

1200W 1400W |

1200W 1400W |

| Voltage | 220V 50Hz | ||

Platform used for flask clamp and tube holder. maximum of flask clamp (Monolayer)

| Model | 101 | 111 | |

|---|---|---|---|

| Flaskclamps (pcs) | 250ml | 27 | 41 |

| 500ml | 16 | 25 | |

| 1000ml | 9 | 15 | |

| 2000ml | 5 | 8 | |

| Rubber mat WxD | (140x140) | 9 | 15 |

| Universal platform | 350x350 | 1 | 2 |

| 400x340 | / | 2 | |

| 450x450 | / | 1 | |

| Note | When closing small size or small quantity, other areas can be equipped with flask clamps or rubber mat | ||