Blog Standard

Online Monitoring of Acid Number and OH Number during Polyester Resin Production

Polyester resins, classified as unsaturated synthetic resins, are renowned for the versatility and extensive range of applications. These resins play a crucial role in various industries, including:

- Automobile and Transportation:Used in sheet molding compounds.

- Kitchen and Restaurants: Incorporated into fiberglass or quartz-reinforced products.

- Infrastructure:Utilized in polyester concrete overlays for roads and bridges.

- Textiles: A key component in the fabric industry

The flexibility of polyester resins stems from their adaptable chemical properties, making them indispensable in both industrial and commercial applications.

Production of Unsaturated Polyester Resins

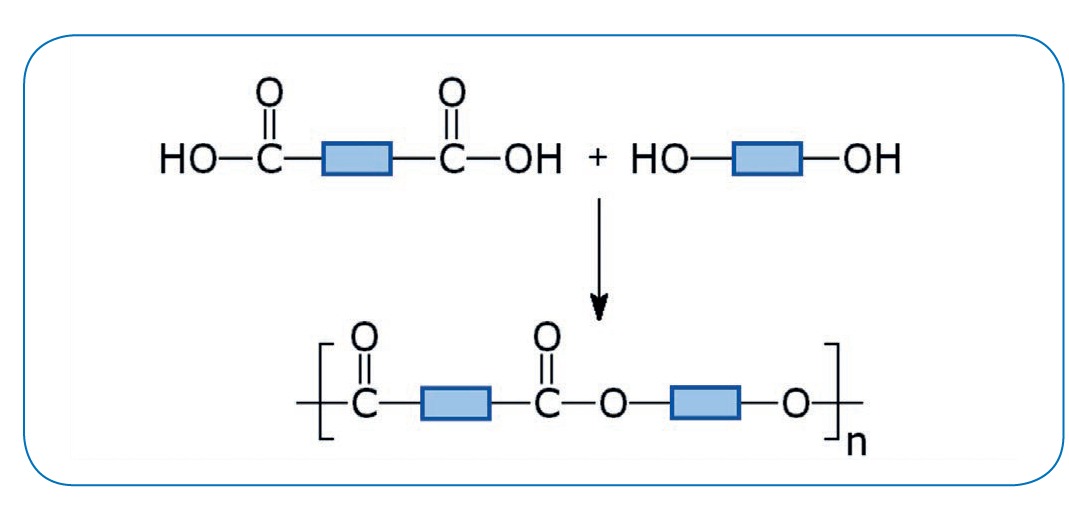

Unsaturated polyester resins are synthesized through the chemical reaction of saturated and unsaturated di-carboxylic acids with alcohols. When cross-linked with a vinyl reactive monomer, these resins form highly durable structures and coatings.

Unsaturated polyester synthesized through the chemical reaction of saturated and unsaturated di-carboxylic acids with alcohols.

The properties of the final cross-linked resins depend on various factors:

- The types of acids and glycols used.

- Their relative proportions.

- The reaction conditions, including temperature (ranging from 185°C to 250°C) and the composition of reactants.

Careful selection of these parameters allows manufacturers to tailor the properties of polyester resins for specific applications.

For instance, the PD-1/PD-L1 checkpoint inhibits immune activity to prevent tissue damage. However, many cancers, including NSCLC, exploit this mechanism by overexpressing PD-L1, effectively evading immune destruction. Therapeutic monoclonal antibodies targeting these interactions have shown promise in reactivating the immune response against tumors. Yet, challenges persist as many patients either do not respond or develop resistance to these therapies due to suboptimal patient selection methods.

Importance of Monitoring Acid and OH Numbers

Throughout the production process, it is essential to monitor key parameters such as Acid Number and OH Number. Real-time monitoring ensures:

- Precise determination of the reaction endpoint.

- Avoidance of defective batches.

- Maintenance of product quality within strict specifications.

FT-NIR process spectroscopy has emerged as a proven and reliable tool for this purpose. It is widely adopted across the industry for its ability to provide accurate, real-time data.

FT-NIR Measurement in Polyester Resin Production

The liquid nature of polyester resin products makes them well-suited for analysis using FT-NIR spectroscopy. Fiber optic transmission probes can be installed directly in the reactor or in a bypass line for continuous monitoring.

The MATRIX-F process spectrometer offers a unique advantage:

- It can monitor up to six measuring points with a single spectrometer, maximizing return on investment.

Bruker MATRIX-F II FT-NIR Process Spectrometer

Additionally, process communication protocols such as Profibus DP, Modbus, OPC DA, or 4-20mA enable seamless data transfer to Distributed Control Systems (DCS). This integration facilitates optimized process control and ensures consistent production quality.

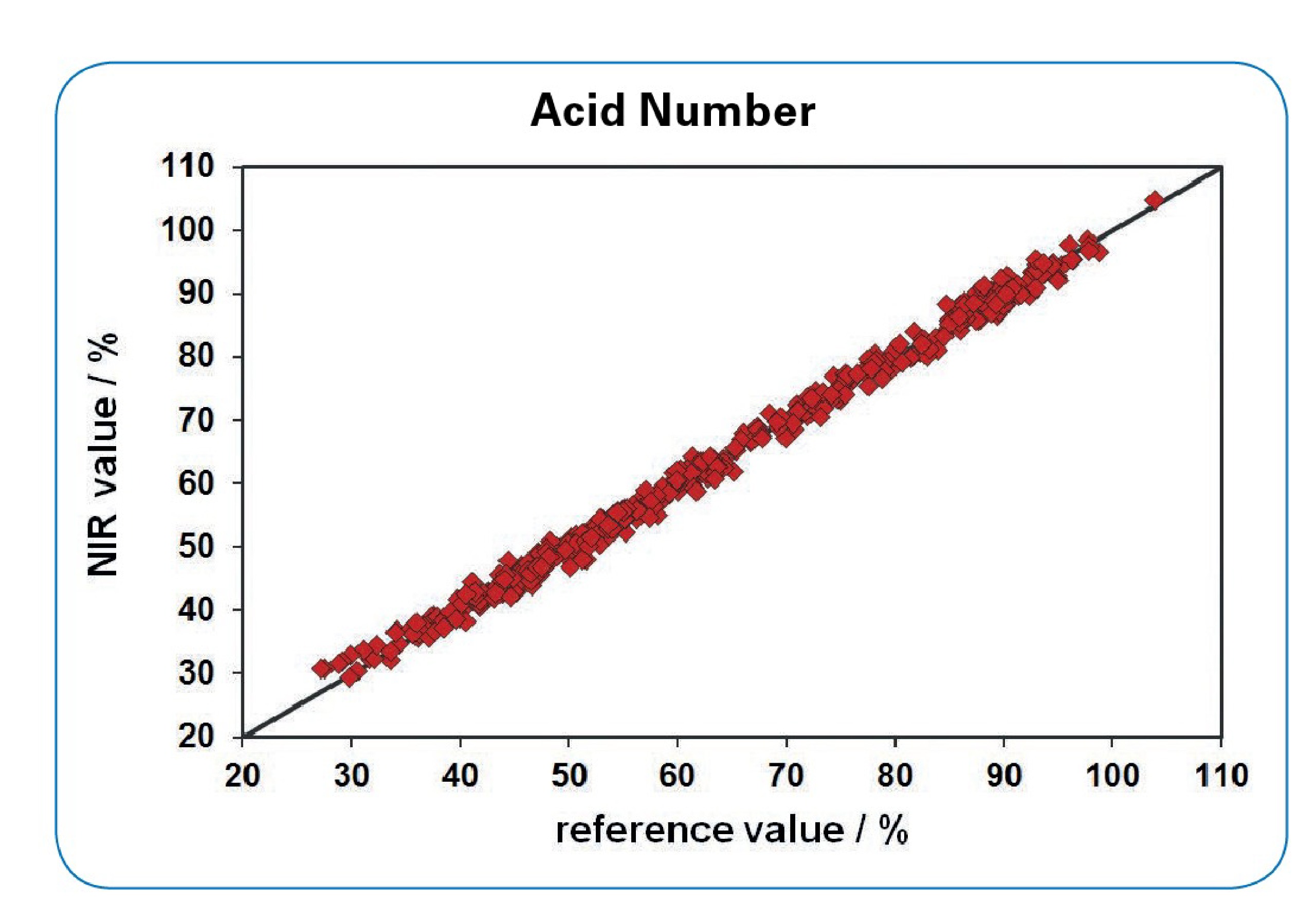

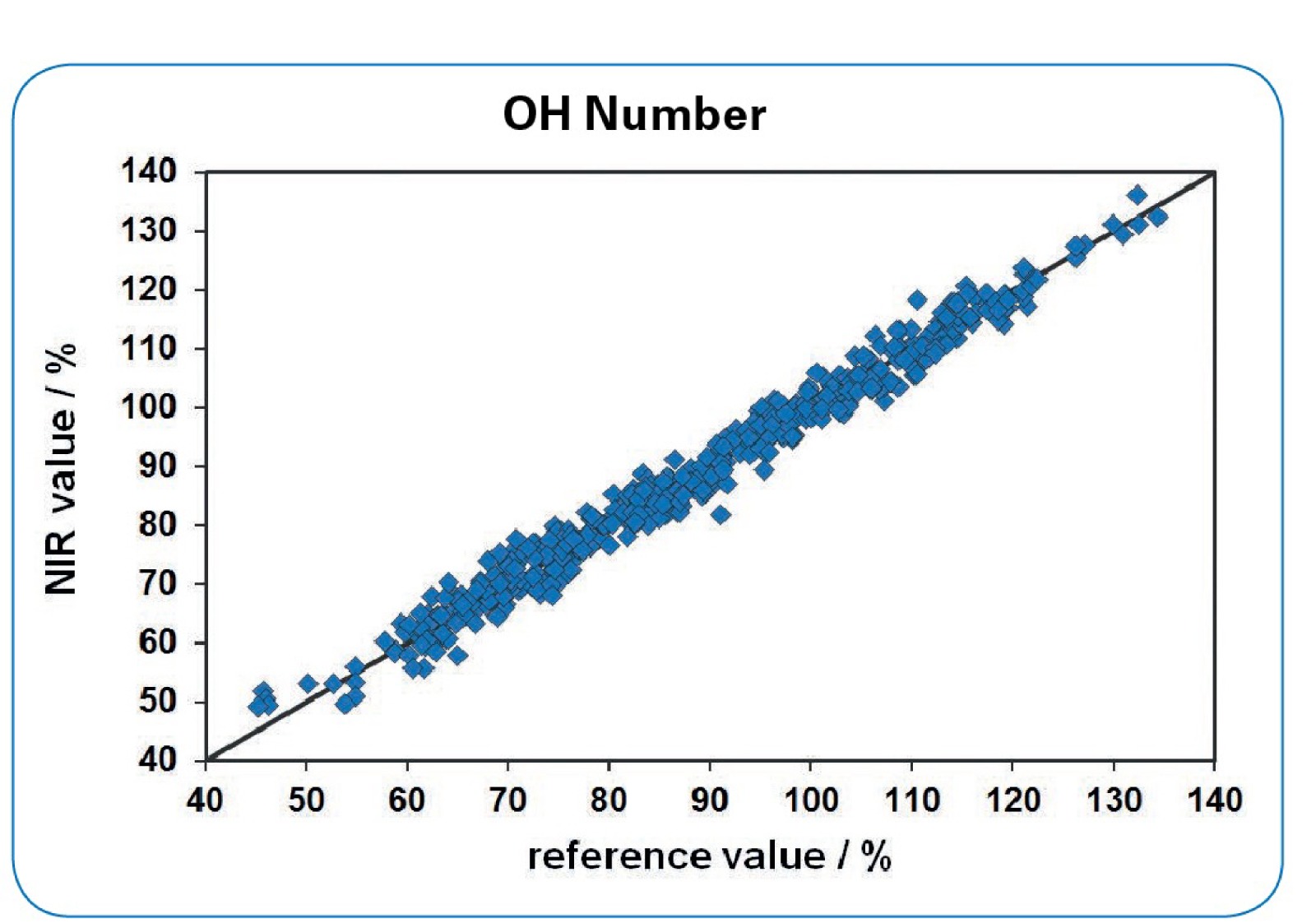

Quantitative Analysis in Polyester Resin Production

Near-infrared (NIR) spectroscopy is a vital analytical technique for studying polyester resin production. NIR spectra are derived from the combination and overtone bands of C-H, N-H, and O-H vibrations, which are abundant in the organic components of reaction mixtures. This makes NIR spectroscopy an ideal tool for analyzing these compounds.

Cross validation results of a PLS based model for the online prediction of the Acid Number during the Polyester reaction.

Cross validation results of a PLS based model for the online prediction of the OH Number during the Polyester reaction.

Innovative Solutions from Bruker Optics

Bruker Optics provides a diverse range of advanced instrumentation designed to meet specific analytical needs in the polyester resin industry:

- TANGO: A cost-effective solution for material identification and quantification across various applications.

- MPA (Multi-Purpose Analyzer): Ideal for laboratory or at-line systems, offering comprehensive solutions for liquid and powder analysis in quality control.

- MATRIX-F: A rugged FT-NIR spectrometer optimized for on-line and in-line process monitoring of liquids and solids using fiber optic probe technologies.

These instruments enable precise monitoring and analysis, ensuring high standards in resin production and beyond.

Conclusion

Polyester resins are a cornerstone in modern industry, offering unparalleled versatility and utility. From their diverse applications to their intricate production process, these resins embody innovation and adaptability. Advanced monitoring technologies, such as FT-NIR spectroscopy and Bruker Optics' state-of-the-art instruments, ensure that production processes meet the highest standards of precision and efficiency.

By leveraging these technologies, manufacturers can produce high-quality polyester resins that meet the evolving demands of various industries, from transportation and infrastructure to textiles and beyond.

Inkarp Instruments, the authorized distributor of Bruker products in India, is widely recognized as the leading distributor and service provider for MATRIX-F II FT-NIR Process Spectrometer. Dedicated to offering cutting-edge scientific solutions, Inkarp guarantees top-tier product quality and dependable support to researchers across the country.

References : Bruker